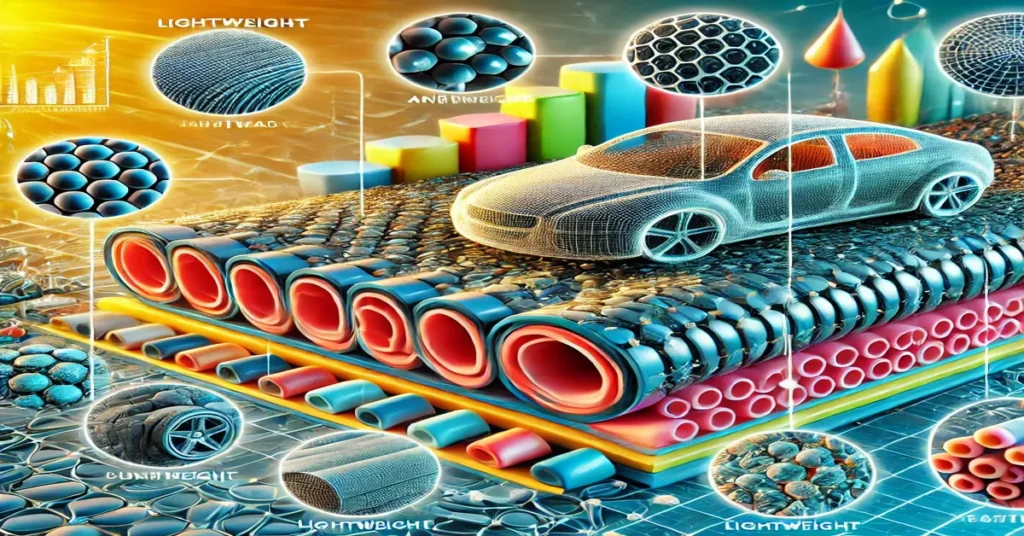

Micro cellular rubber, often referred to as microcellular foam rubber, is a versatile material renowned for its resilience, flexibility, and diverse applications. This specialized rubber is characterized by its unique cellular structure, which provides an exceptional combination of lightweight properties, cushioning ability, and durability. In this article, we will delve deep into the composition, properties, manufacturing processes, types, applications, advantages, and environmental considerations of micro cellular rubber.

What is Micro Cellular Rubber?

Micro cellular ruber is a synthetic elastomer material featuring a cellular structure with numerous small, evenly distributed closed or open cells. These cells, filled with gas or air, contribute to the material’s lightweight and elastic properties. This rubber is widely used in various industries, including automotive, electronics, footwear, and construction, due to its ability to absorb shocks, resist compression, and maintain dimensional stability under stress.

Composition of Micro Cellular Rubber

Micro cellular rubberr is primarily composed of the following elements:

- Base Polymers: These include natural rubber (NR), synthetic rubbers such as ethylene-propylene-diene monomer (EPDM), styrene-butadiene rubber (SBR), nitrile rubber (NBR), or silicone rubber.

- Blowing Agents: These are used during manufacturing to create the cellular structure by producing gas bubbles within the rubber matrix.

- Fillers: Materials like carbon black, silica, and clay are added to enhance the strength and stability of the rubber.

- Additives: Compounds such as plasticizers, antioxidants, and curing agents are incorporated to improve the performance and longevity of the rubber.

Key Properties of Micro Cellular Rubber

Micro cellular rubberr exhibits several desirable properties, making it suitable for a wide range of applications. These include:

- Lightweight: The cellular structure significantly reduces the density of the material.

- Elasticity: The rubber can recover its shape after deformation, providing excellent cushioning.

- Shock Absorption: It absorbs and dissipates impact energy effectively.

- Thermal Insulation: The air-filled cells act as thermal insulators.

- Sound Dampening: Micro rubber reduces noise transmission.

- Weather Resistance: Certain formulations are resistant to UV rays, ozone, and extreme temperatures.

- Chemical Resistance: Depending on the base polymer, the material may resist oils, solvents, and other chemicals.

- Water Resistance: Closed-cell variants prevent water ingress, making them ideal for outdoor and aquatic applications.

Manufacturing Process

The production of micro cellular rubber involves several steps, each critical to achieving the desired cellular structure and properties. The process typically includes:

1. Compounding

Raw materials such as polymers, fillers, and additives are mixed to form a homogeneous compound.

2. Blending with Blowing Agents

Chemical or physical blowing agents are introduced to the rubber compound. These agents release gases during processing, creating the cellular structure.

3. Shaping

The compound is shaped into sheets, blocks, or specific forms using extrusion, molding, or calendaring techniques.

4. Curing and Vulcanization

The shaped rubber is heated to activate the blowing agents and initiate vulcanization, which strengthens the material by forming cross-links between polymer chains.

5. Post-Processing

The material may undergo cutting, laminating, or coating to achieve the desired dimensions and surface properties.

Types of Micro Cellular Rubber

Micro cellular rubber is available in various forms, each tailored to specific applications:

1. Closed-Cell Rubber

This type features isolated gas-filled cells that do not interconnect. It is impermeable to water and air, making it ideal for sealing and insulation.

2. Open-Cell Rubber

The interconnected cells in open-cell rubber allow air and moisture to pass through. It is commonly used for cushioning and soundproofing.

3. Blended Variants

Some micro cellular rubberrs combine closed- and open-cell structures to balance breathability and water resistance.

4. Specialized Formulations

High-performance rubbers with enhanced properties, such as flame resistance or bio-compatibility, are used in niche applications like aerospace and medical devices.

Applications of Micro Cellular Rubber

The versatility of micro cellular rubber lends itself to numerous industries and applications:

1. Automotive

- Sealing: Used in door gaskets, weatherstrips, and under-hood seals.

- Vibration Dampening: Reduces vibrations in engine mounts and suspension components.

- Noise Reduction: Applied in dashboards and cabin interiors for soundproofing.

2. Electronics

- Insulation: Protects sensitive electronic components from dust, moisture, and mechanical shocks.

- Gaskets: Ensures secure seals in devices like smartphones and laptops.

3. Footwear

- Cushioning: Provides comfort and impact absorption in shoe soles and insoles.

- Durability: Enhances the longevity of footwear by resisting wear and tear.

4. Construction

- Thermal Insulation: Used in HVAC systems and building materials to improve energy efficiency.

- Weatherproofing: Seals and protects structures from environmental elements.

5. Healthcare

- Orthotics and Prosthetics: Provides comfort and support in medical devices.

- Pads and Cushions: Used in hospital beds and wheelchairs.

6. Packaging

- Protective Padding: Safeguards fragile items during transportation.

- Reusable Components: Durable pads for industrial and consumer goods.

7. Sports and Recreation

- Safety Gear: Found in helmets, padding, and mats.

- Equipment: Provides grip and cushioning in sports equipment.

Advantages of Micro Cellular Rubber

- Versatility: Suitable for diverse applications across multiple industries.

- Durability: Resists aging, wear, and harsh environmental conditions.

- Eco-Friendliness: Certain types can be recycled or manufactured with reduced environmental impact.

- Customization: Available in various densities, thicknesses, and formulations to meet specific requirements.

- Cost-Effectiveness: Offers a good balance of performance and affordability.

Environmental Considerations

1. Sustainability

Manufacturers are increasingly adopting eco-friendly practices, such as using renewable materials and minimizing waste during production.

2. Recyclability

Some types of micro cellular rubber can be recycled, reducing their environmental footprint.

3. Alternatives to Toxic Components

The industry is moving towards non-toxic blowing agents and additives to ensure safer products and processes.

Future Trends

- Innovation in Materials: Development of biodegradable and bio-based rubbers.

- Enhanced Performance: Research into nano-composites and advanced fillers.

- Automation: Use of AI and robotics in manufacturing for precision and efficiency.

- Sustainability Focus: Greater emphasis on lifecycle analysis and eco-friendly designs.

Conclusion

Micro cellular rubber is an indispensable material in modern industry, valued for its unique combination of properties and adaptability. From automobiles to medical devices, its applications continue to expand as technology advances and sustainability becomes a priority. Understanding its properties, manufacturing processes, and applications allows businesses and consumers to leverage its benefits effectively.

FAQs

1. What is micro cellular rubber used for?

Micro cellular rubber is used in industries such as automotive, electronics, construction, healthcare, and sports for applications like sealing, cushioning, insulation, and vibration dampening.

2. What is the difference between closed-cell and open-cell micro cellular rubber?

Closed-cell rubber has isolated cells that make it impermeable to water and air, while open-cell rubber has interconnected cells, allowing air and moisture to pass through.

3. How is micro cellular rubber made?

It is made by mixing polymers with blowing agents and additives, shaping the compound, and curing it to create a cellular structure.

4. Is micro cellular rubber environmentally friendly?

Certain types can be eco-friendly, especially those made with recyclable materials or non-toxic blowing agents. However, sustainability depends on the specific formulation and manufacturing process.

5. What are the advantages of using micro cellular rubber in footwear?

It provides excellent cushioning, impact absorption, durability, and lightweight properties, enhancing comfort and longevity.

6. Can micro cellular rubber be customized?

Yes, it can be tailored in terms of density, thickness, and composition to meet specific application requirements.