Brazering is a versatile and widely used method of joining metals and other materials. By using a filler metal, brazing creates strong bonds that can withstand high temperatures and various environmental conditions, making it a preferred technique across many industries, including automotive, aerospace, HVAC, plumbing, and electronics.

This article delves into the fundamentals of brazing, its types, the process involved, applications, and advantages over other joining techniques. Whether you’re a professional or a hobbyist interested in metalwork, understanding brazing can help you make informed choices in material joining.

Table of Contents

- Introduction to Brazing

- How Brazing Works

- Types of Brazing

- Advantages and Disadvantages of Brazing

- Brazing Applications Across Industries

- Brazing Techniques and Equipment

- Safety Considerations in Brazing

- Conclusion

- FAQs

1. Introduction to Brazing

Brazing is a joining process that involves heating a filler metal above its melting point and flowing it into the gap between closely fitting metal parts. Unlike welding, where the base metals are melted together, brazing only melts the filler material, allowing it to bond the metals without altering their properties. This characteristic makes brazing ideal for delicate or complex assemblies where retaining the base metal properties is crucial.

Historically, brazing has been used for centuries, with evidence of its use dating back to ancient Egypt and China. Its reliability and strength have made it a go-to joining method, even as modern technologies have emerged.

2. How Brazing Works

In brazing, the parts to be joined are first cleaned and closely aligned. A filler metal, typically with a lower melting point than the base metals, is introduced, either in the form of a rod, paste, or pre-placed filler alloy. As the assembly is heated, the filler metal melts and flows into the joint by capillary action. Once cooled, the filler solidifies, creating a strong bond between the parts.

Key factors in brazing include:

- Filler Metal: The choice of filler metal is critical and is based on compatibility with the base metals, melting point, and intended application.

- Flux: Flux is a chemical agent used in brazing to prevent oxidation, which can weaken the bond. It cleans the metal surfaces and promotes filler flow.

- Heat Source: Common heat sources include torches, furnaces, induction heating, and infrared.

3. Types of Brazing

Brazing is a versatile process with different techniques available, each suited to specific materials, designs, and production needs.

a. Torch Brazing

Torch brazing uses a gas-fed torch to heat the assembly. It’s a common method for small-scale and repair applications.

b. Furnace Brazing

In furnace brazing, the parts are heated in a controlled atmosphere furnace. This method is efficient for mass production as it allows multiple parts to be brazed simultaneously.

c. Induction Brazing

Induction brazing uses an electromagnetic field to generate heat in the metal. It’s precise, fast, and suitable for high-volume production or parts with localized heating requirements.

d. Dip Brazing

Dip brazing involves immersing the parts in molten salt or filler metal. This method is often used for complex assemblies and non-ferrous metals, like aluminum.

e. Vacuum Brazing

Vacuum brazing occurs in a vacuum chamber, preventing oxidation and contamination. This process is commonly used in aerospace and medical applications due to its strength and cleanliness.

Each type of brazing has unique characteristics that make it suitable for specific applications and industries.

4. Advantages and Disadvantages of Brazing

Advantages of Brazing

- Non-Melting of Base Metal: Brazing preserves the integrity of the base metal, which is critical in delicate applications.

- Versatility: Brazing can join dissimilar metals, such as copper to stainless steel, which is challenging in welding.

- Clean and Precise: Brazing creates clean joints with minimal finishing, which is advantageous in applications where aesthetics matter.

- Strength and Durability: Brazed joints are strong, often equal to or stronger than the base metals.

- Cost-Effective: Brazing can be more economical than welding, especially for small or thin parts.

Disadvantages of Brazing

- Lower Joint Strength Compared to Welding: While strong, brazed joints typically don’t match the strength of welded joints.

- Temperature Limitations: Brazed joints may weaken at high temperatures.

- Need for a Clean Environment: Oxidation or contamination can compromise the brazed joint, requiring careful cleaning and flux application.

5. Brazing Applications Across Industries

Brazering is an essential process in many industries due to its adaptability and ability to create strong joints with minimal thermal distortion.

Automotive Industry

Brazing is used to join components in engines, radiators, and air conditioning systems. The ability to join dissimilar metals, like aluminum to copper, is particularly beneficial in automotive applications.

Aerospace Industry

In aerospace, brazing is used for turbine blades, fuel lines, and structural components. The strength and precision of brazed joints make it ideal for high-stress environments.

Electronics and Electrical Industry

Brazering is crucial for connecting wires, circuits, and components in electronics, ensuring reliable electrical connections.

HVAC Industry

Brazing is commonly used in HVAC systems to join copper tubes, compressors, and coils, where durability and leak-proof joints are essential.

Plumbing

Brazering is widely used to join copper pipes in plumbing, providing reliable, leak-proof joints that withstand pressure.

Jewelry Making and Art

In jewelry, brazing is used to join precious metals. It provides strong, seamless joints, preserving the appearance and value of the pieces.

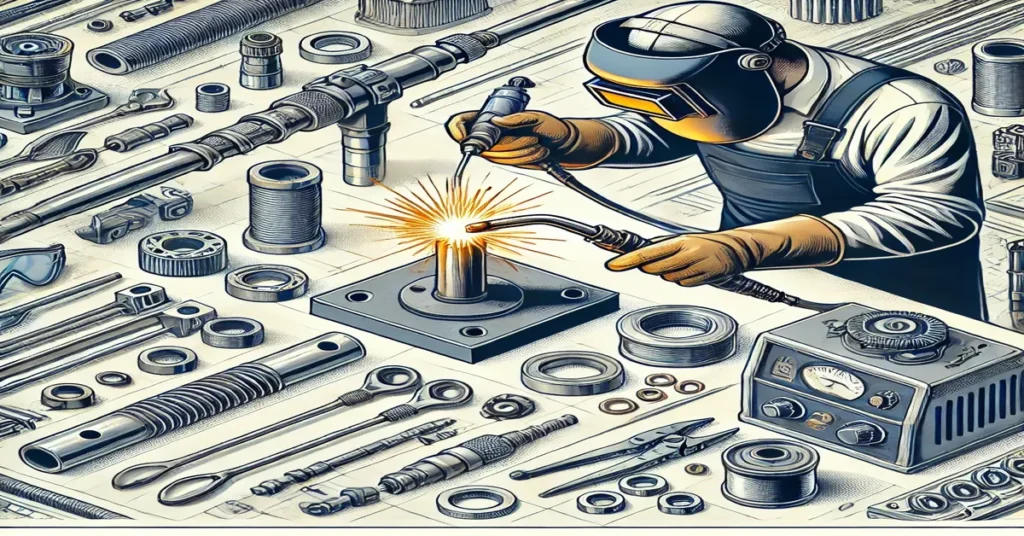

6. Brazing Techniques and Equipment

The brazering process requires specific equipment and techniques, which vary depending on the materials, joint design, and application requirements.

Basic Steps in Brazing

- Cleaning: Clean the surfaces to remove contaminants that could weaken the joint.

- Flux Application: Apply flux to prevent oxidation.

- Assembly: Align and position the parts to ensure an even gap for the filler metal.

- Heating: Heat the joint area until the filler metal flows, using a torch, furnace, or induction heating.

- Cooling: Allow the joint to cool and solidify, creating a durable bond.

- Post-Cleaning: Remove any residual flux or oxidation, as it can affect the joint’s appearance and longevity.

Equipment Used in Brazing

- Torches: Common for small-scale applications, typically fueled by acetylene, propane, or natural gas.

- Furnaces: Used for large-scale, consistent heating.

- Induction Heaters: Precise and efficient, suitable for specific metals.

- Brazing Rods: Available in various alloys based on the base metals being joined.

- Flux: Essential for preventing oxidation and improving filler flow.

7. Safety Considerations in Brazing

Brazering involves high temperatures and potentially harmful chemicals, making safety a priority.

Personal Protective Equipment (PPE)

- Gloves: Heat-resistant gloves protect against burns.

- Eye Protection: Safety glasses or goggles shield the eyes from heat and sparks.

- Respirators: Some fluxes emit fumes that may require a respirator.

- Aprons: Fire-resistant aprons protect clothing and skin from sparks.

Ventilation

Good ventilation is crucial when brazing, especially in confined spaces. Proper ventilation removes toxic fumes and smoke, reducing inhalation risks.

Proper Handling of Chemicals

Flux and cleaning agents contain chemicals that can be hazardous. Store them safely and handle them with gloves to avoid skin contact.

Conclusion

Brazering is a valuable joining technique that combines strength, precision, and adaptability. With applications in diverse fields from automotive to jewelry making, brazing enables the creation of reliable joints between similar and dissimilar metals. Whether you’re a professional welder, an engineer, or a hobbyist, understanding brazing can help you make informed choices in material joining.

From its ability to join intricate parts without melting the base metal to its suitability for high-stress applications, brazering offers a range of benefits. With the right equipment, technique, and safety precautions, brazing can be a cost-effective and efficient choice for joining metal components.

FAQs

1. What is the main difference between brazing and welding?

Brazing joins metals by melting a filler metal without melting the base metals, whereas welding melts both the filler and base metals to create a joint.

2. Can brazing join different types of metals?

Yes, brazing can join dissimilar metals, such as copper to aluminum or stainless steel, which is challenging in other joining methods.

3. Why is flux used in brazing?

Flux prevents oxidation and helps the filler metal flow more effectively, creating a cleaner, stronger joint.

4. Is brazing as strong as welding?

While brazing is strong, it generally doesn’t provide the same joint strength as welding, especially for high-load applications.

5. What temperature is needed for brazing?

Brazing typically requires temperatures between 800°F and 2,000°F, depending on the filler metal and materials used.

6. Can brazing be done at home?

Yes, with the right tools and safety precautions, brazing can be done at home for small projects or repairs.